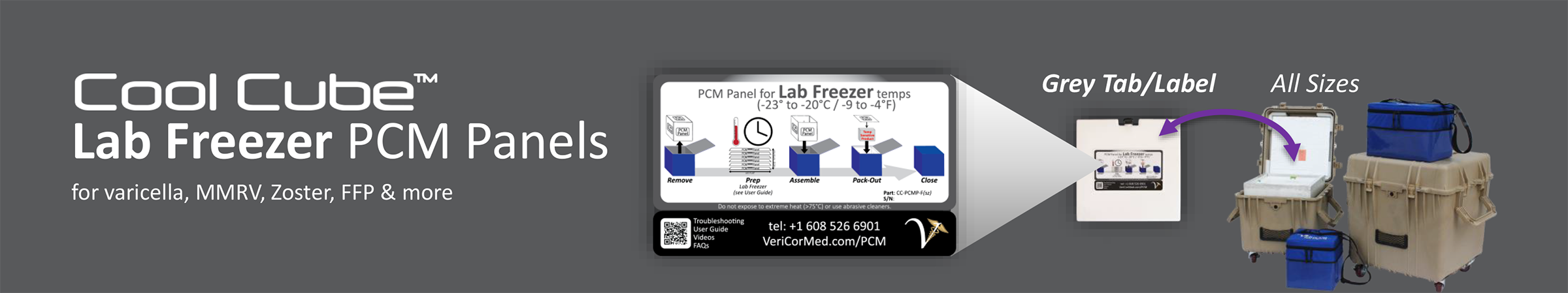

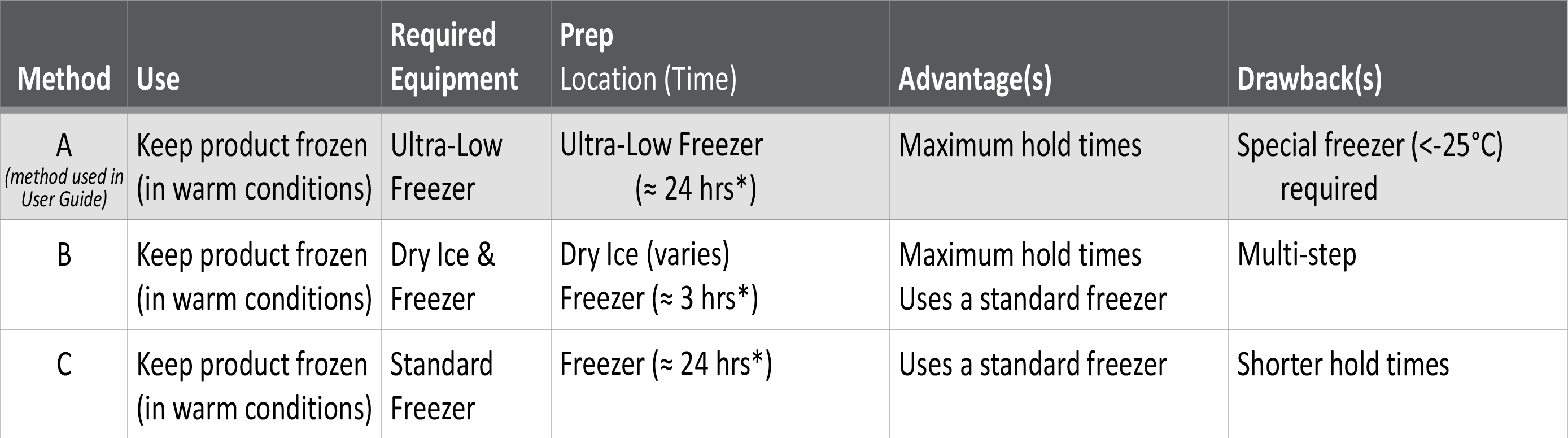

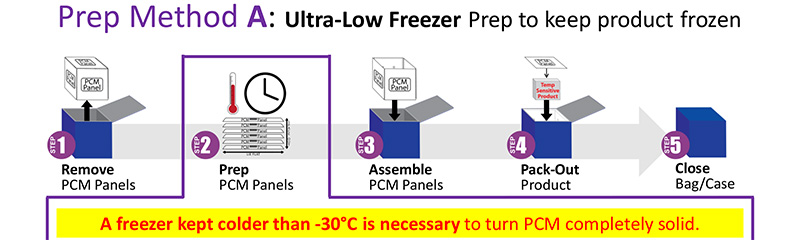

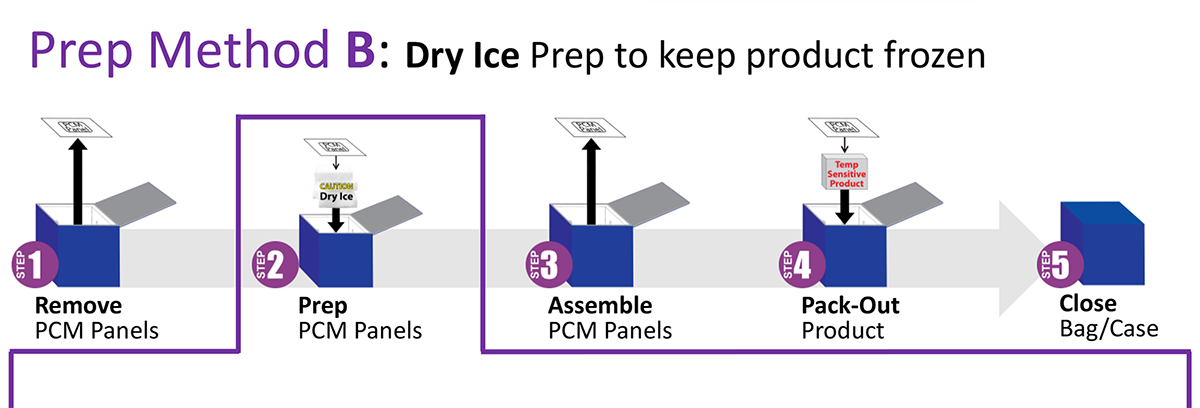

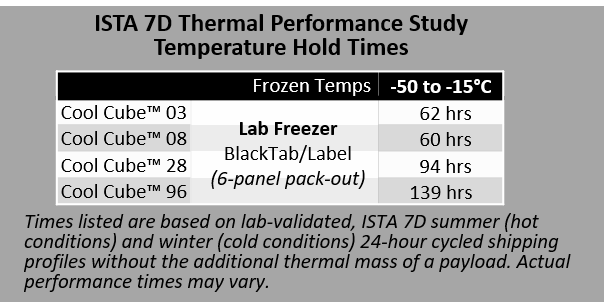

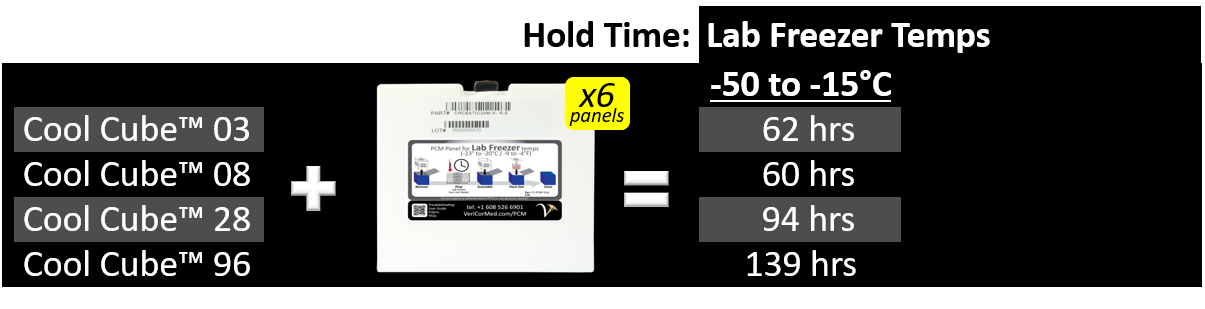

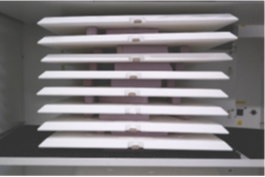

The Cool Cube™ 28 at Lab Freezer Temperatures (FT-28) is not an ordinary transport cooler (frozen vaccine and FFP carrier). It is an easy-to-carry, qualified container and pack-out system that keeps temperature sensitive product such as varicella, MMRV, zoster or fresh frozen plasma, frozen between -50 and -15°C for over 2.5 days – without using ice or electricity! This cooler is ideal for transport, but also excels at protecting valuable product during off-site use and power outages, regardless of hot conditions. The simple, validated, patented technology is the best compact thermal protection product available to maintain the cold chain! NOTE: An ultra-low freezer capable of holding a -30°C/-22°F or lower temperature is needed to prep the panels for maximum hold time.

Technology & Features

![]() Phase Change Technology

Phase Change Technology

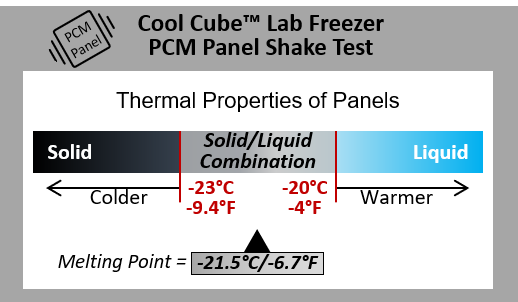

Cool Cube™ PCM (phase change material) is engineered to maintain a constant temperature at a specific melt/freeze point. PCM empowers the user with a safe, effective means to maintain the temperature of valuable product.

![]() Temp-Shield™ Insulation

Temp-Shield™ Insulation

Vacuum insulated panels (VIPs) offer advanced thermal protection far superior to other types of insulation. The temperature-holding qualities ensures the user a long-lasting, consistent temperature hold for days.

![]() Transport Case

Transport Case

Each outer case is built with mobility in mind. Various features enable the user to move with confidence and know the contents are well protected (and at the correct temperature) during transit and use.

Additional Features

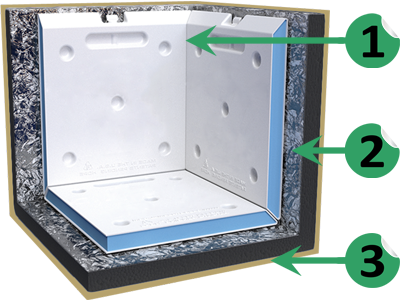

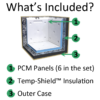

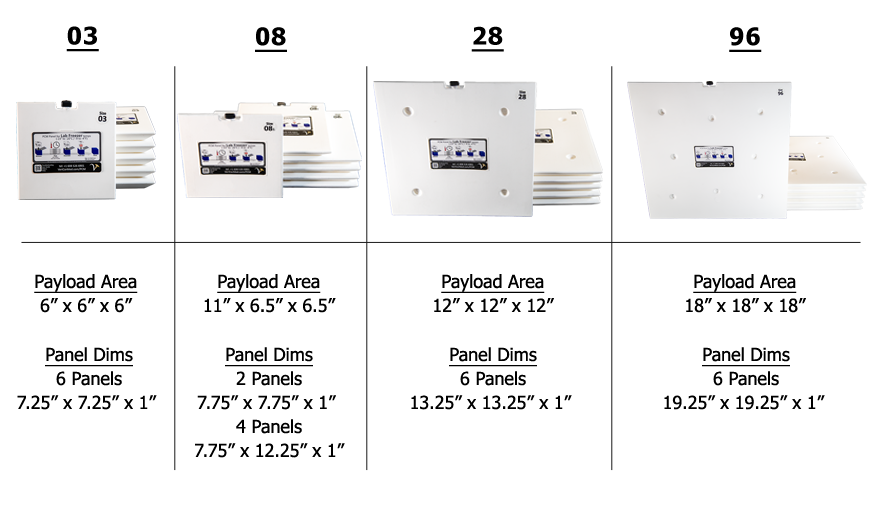

PCM Panels

VIP System

- Six panels for lab freezer temperatures included.

- Patented, beveled-edge design seamlessly fit together.

- Panels are interchangeable with other temperature systems.

- Reusable (10,000+ cycles)

- Reinforced, clear-plastic, protective wrap.

- Rigid structure is durable and light.

- 5x the resistance (R-value) of conventional insulation.

- Removable and replaceable.

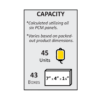

Dimensions & Specs

Outside: 20½” x 20½” x 23”

Inside: 12″ x 12″ x 12″

Weight: 70 lbs.

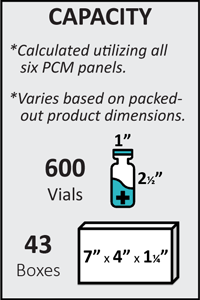

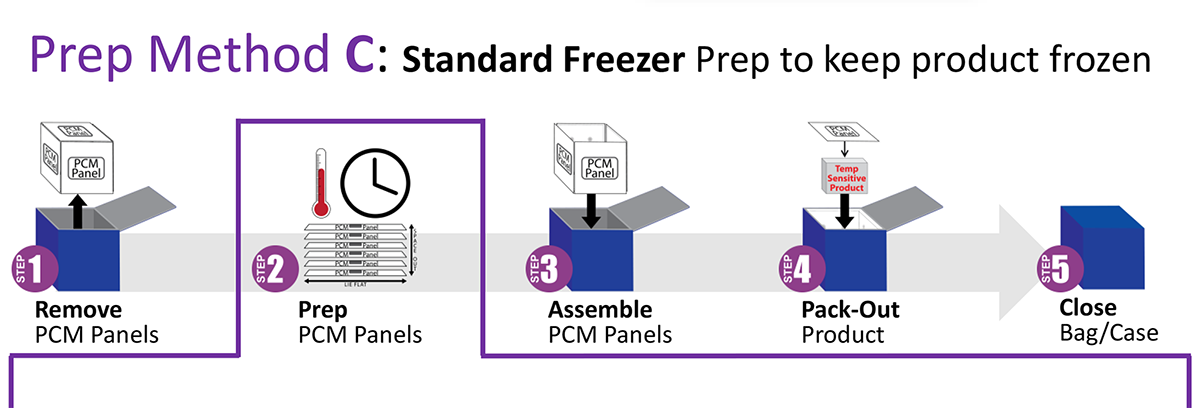

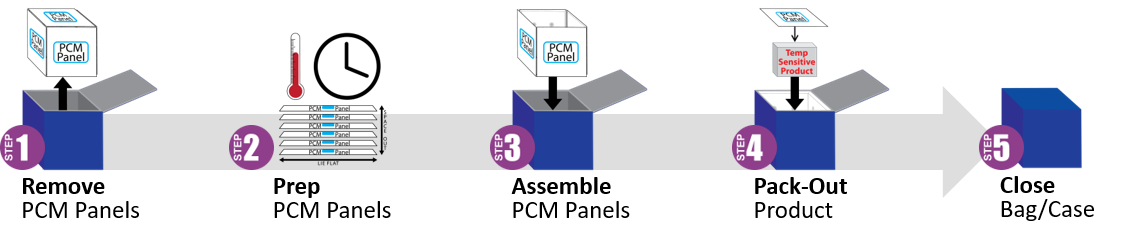

Easy & Safe Pack-Out

EXTENDED TRANSPORT

No worries for several days! This validated system will hold -50 to -15°C (-58° to 5°F) for an extended time, even in harsh environments. It is long-lasting, passive temperature-controlling technology when you need it most.

OFF-SITE INITIATIVES

Ideal for outreach clinics and field missions! This easy-to-use system eliminates the complicated steps found with other methods, and simplifies/expedites the pack-out process. Packed with mobility features, it can go anywhere it’s needed.

EMERGENCY BACKUP

A great solution to keep things safe during power outages! Since it does not rely on ice or electricity, next time the freezer goes down have this storage AND transport solution as a backup. Reduce the risk with a Cool Cube™.

You must be logged in to post a comment.