A Cool Cube™ Vaccine Transport Cooler is no ordinary vaccine cooler. The Cool Cube™ is a reliable cold chain management system. It is an easy-to-carry, qualified container and pack-out system that keeps temperature sensitive product such as fresh vaccine and medicine chilled between 2° and 8°C for over 2.5 days – without using ice or electricity! This cooler is ideal for transport, but also excels at protecting valuable product during off-site use and power outages, regardless of hot or freezing conditions. The simplified, validated, patented technology is the best compact thermal protection product available to maintain the cold chain!

Transport & Storage Coolers @ Refrigerator Temps for Vaccine, Medicine, etc.

Refrigerator Cool Cube™ Technical Information

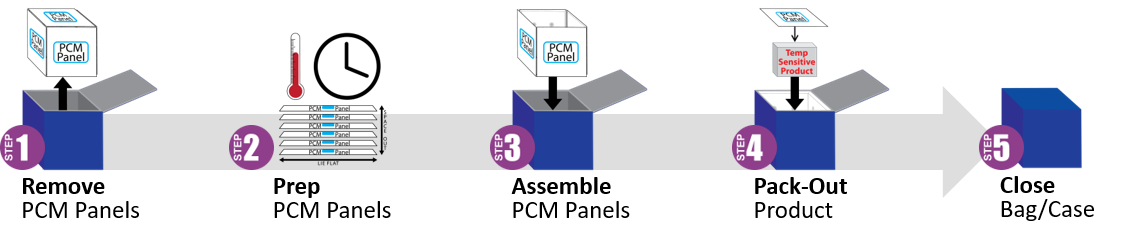

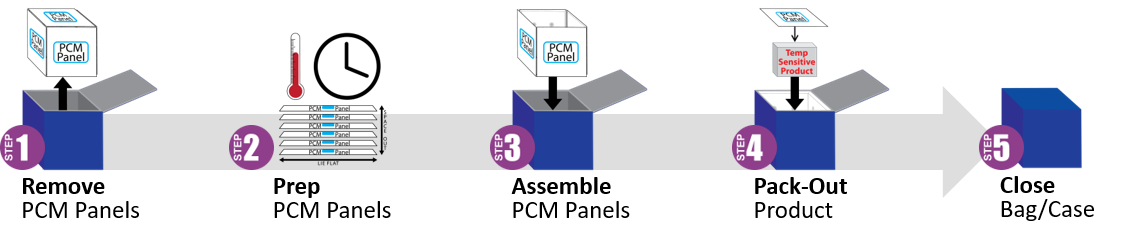

Easy & Safe Pack-Out

Cool Cube™ Refrigerator Temp Training Videos

Cool Cube™ Refrigerated – Prep Introduction

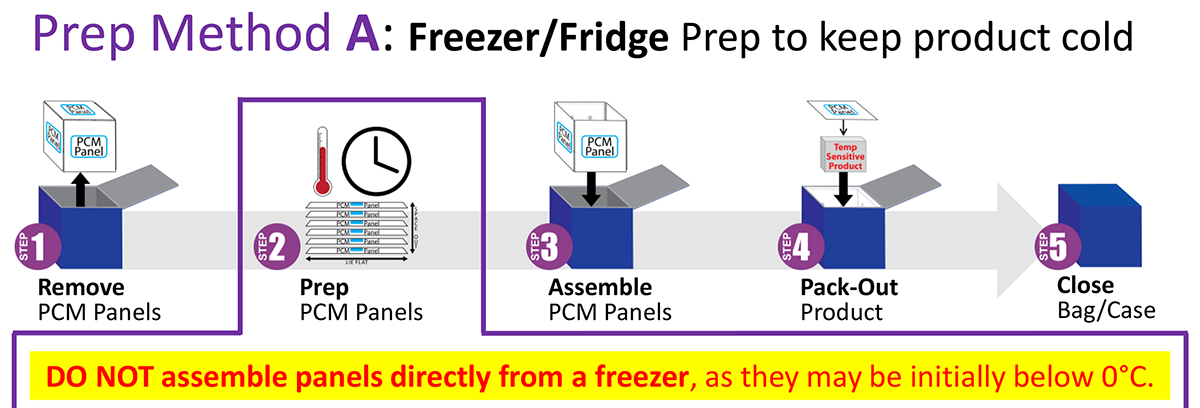

Prep Method A – Keep product cold (in warm conditions)

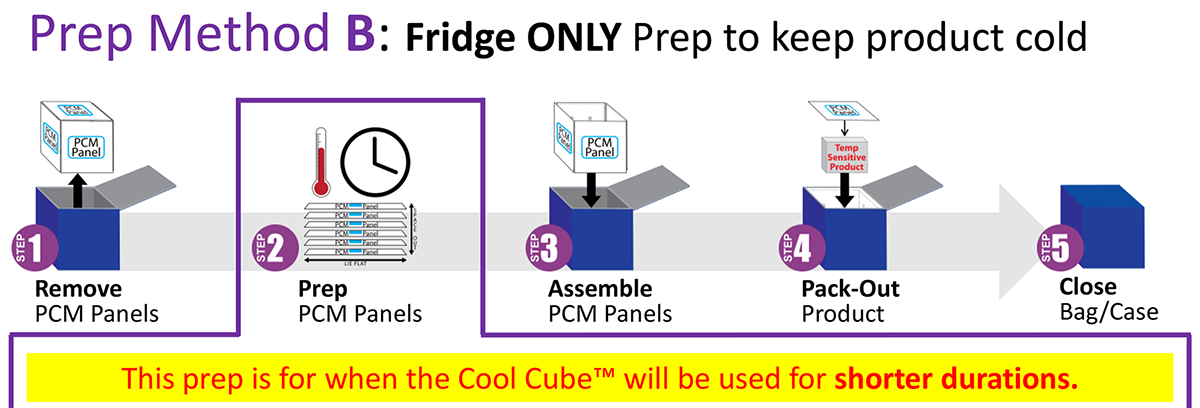

Prep Method B – Keep product cold (in warm conditions)

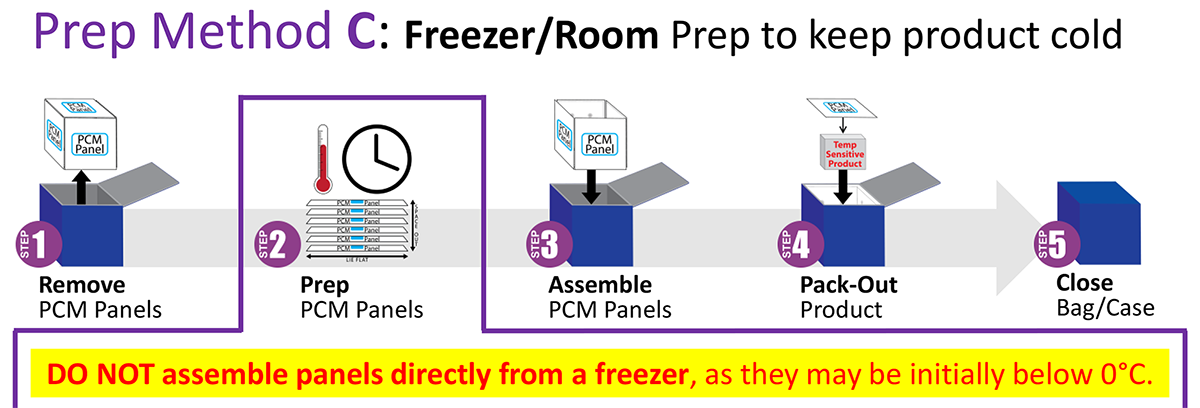

Prep Method C – Keep product cold (in warm conditions)

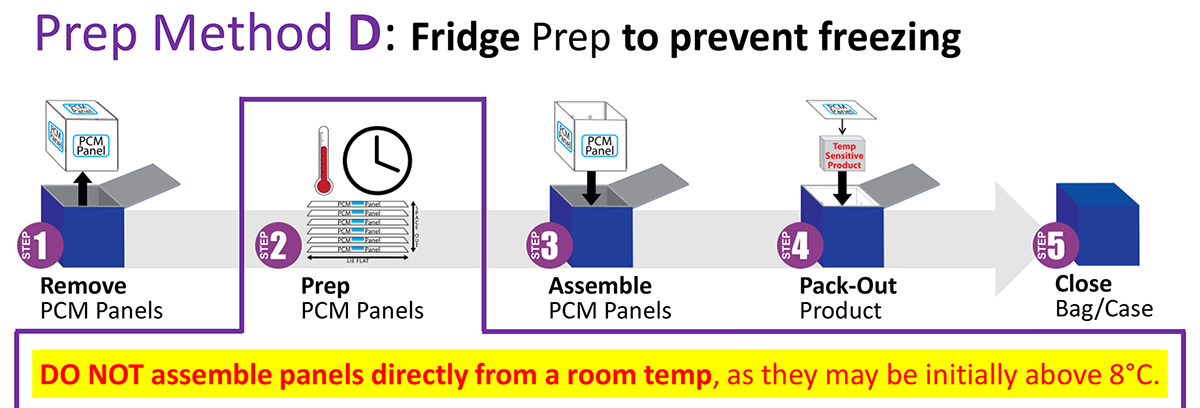

Prep Method D – Prevent freezing (in extreme cold)

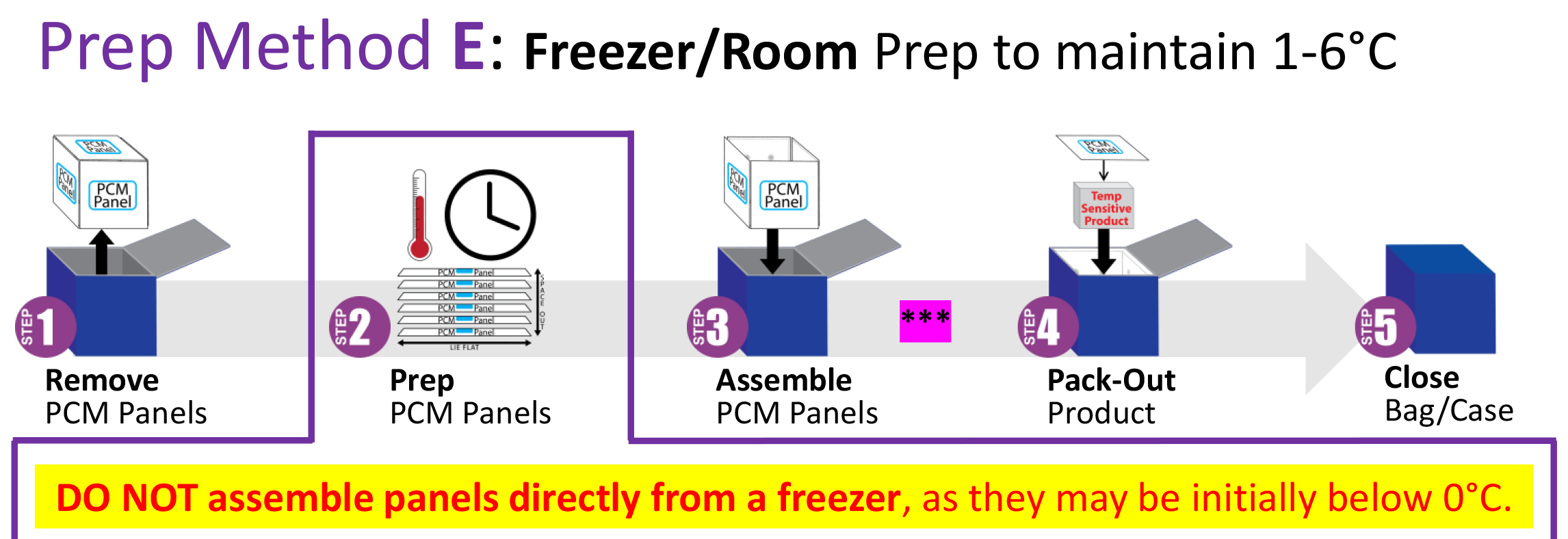

Prep Method E – Keep product cold (in warm conditions)

* Freezer/Room Prep to maintain 1-6°C

Refrigerator Cool Cube™ Preparation Methods

- *Panels may be stored at this stage indefinitely (for longer than indicated).

About Refrigerator PCM (Phase Change Material)

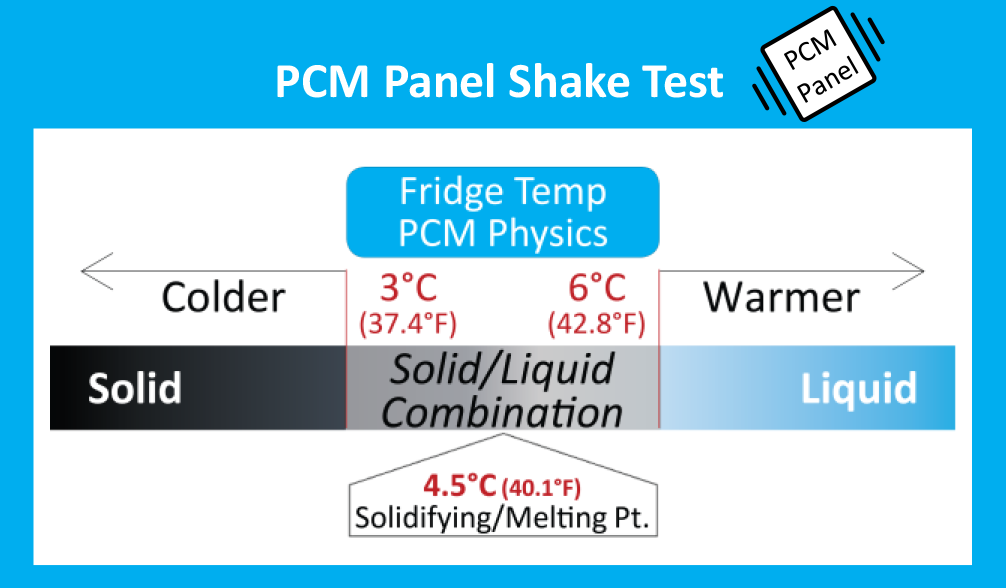

PCM absorbs and releases thermal energy during the process of melting and freezing. When solid PCM melts, it absorbs the heat from the environment, yet its temperature stays at the melting point until totally liquid. Conversely, when liquid PCM freezes, it absorbs the cold from the environment yet stays at its temperature until totally solid. Therefore, PCM an ideal, passive solution for a variety of applications that require temperature control. The most common PCM is water, which has a melting point of 0 °C (32 °F). When solid, ice/water maintains a temperature of 0 °C until it turns completely liquid. So, in essence, the 0 °C melting point makes it unsafe for most refrigerator temperature sensitive applications.

Cool Cube™ Refrigerator PCM has a melting point of 4.5 °C/40.1 °F. When the PCM is solid, a panel helps the Cool Cube ™stay cool (about 5 °C) in warm/hot environments. When the PCM is liquid, a panel helps the Cool Cube ™stay warm (about 4 °C) in freezing conditions. It’s right around that 4.5 °C/40.1 °F where a PCM panel’s temperature plateaus for a while during the warming up and/or cooling down processes.

Refrigerated 4 Prep Method A: Freezer to Fridge Pack-Out Instructions

Panel Prep

2.1 Lay panels flat in a freezer until all the PCM (phase change material inside the panel) turns solid. At -15°C/5°F the PCM will solidify in a couple hours.

2.2 Transfer panels into a fridge at least 3 hours before use. Panels may be stored in the fridge until needed for assembly or until the PCM melts.*

- * If a fridge maintains 4°C/39°F or below, the PCM within the panels will not melt (melting point is 4.5°C/40°F), which will keep the panel solid indefinitely until pack-out. If the fridge maintains 5°C/41°F or above, periodically check for melting and restart at step 2.1 to ensure optimal performance.

2.3 Shake panels to verify the PCM is solid. If there is liquid, restart at step 2.1 to ensure the longest hold time. Using liquid PCM or panels with a solid/liquid combination decreases the hold time.

Refrigerated Prep Method B: Fridge Only Pack-Out Instructions

Panel Prep

2.1 Lay panels flat in a refrigerator for a minimum of 24 hours before use.

2.2 Shake panels to check the state of the PCM (phase change material inside the panel).

- If liquid…panel is at the fridge temp but above 5°C; anticipate shorter hold times.

- If solid…panel is at the fridge temp but below 4°C; ideal for maximum hold times.

- If solid/liquid combination…panel is at the fridge temp of 4-5°C; monitor time/temp.

In a refrigerator that maintains 4°C or below, the PCM will be solid (ideal for keeping product cold in warm/hot conditions). In a refrigerator that maintains 5°C or above, the PCM will be liquid. Although the PCM is liquid, the panel is at the temperature of the storage environment after 3 hours (i.e., stored in a 6°C fridge, the panels are at 6°C). Assembling the Cool Cube™ with liquid PCM panels (additional thermal mass) will help keep the product at its temperature, just for a shorter amount of time. Monitor Cool Cube™ temperature closely.

Refrigerated Prep Method C: Freezer to Room Pack-Out Instructions

Panel Prep

2.1 Lay panels flat in a freezer until all the PCM (phase change material inside the panel) turns solid. At -15°C/5°F the PCM will solidify in a couple hours.

2.2 Transfer panels into a room temperature environment just before use to allow the PCM inside to rise to the appropriate operating temperature. Approximate times:

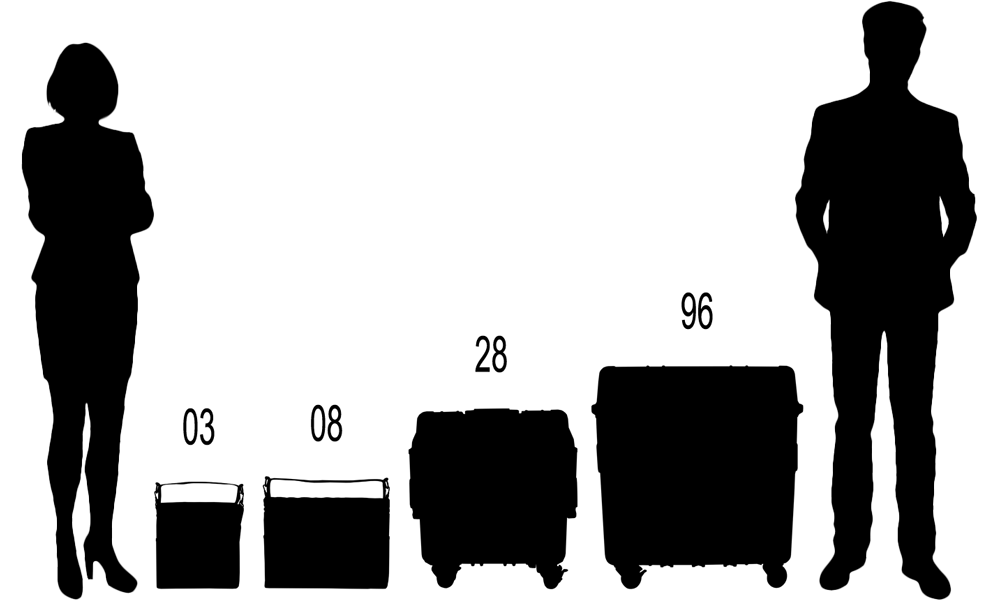

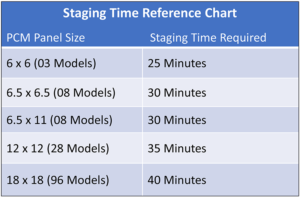

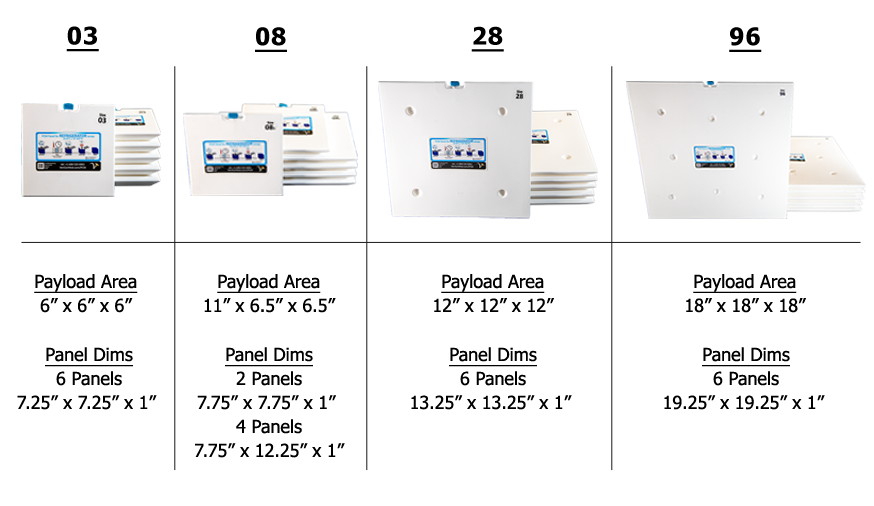

- “03” size = 25 minutes

- “08” size = 30 minutes

- “28” size = 35 minutes

- “96” size = 40 minutes

- **Times based on a 22°C/72°F room.

2.3 Wipe off condensate. After frost turns to condensate, the panel is above 0°C.

2.4 Shake panels to verify the PCM is solid. If a little liquid is heard, it is at 4.5°C. If there is a lot of liquid, restart at step 2.1 to ensure the longest hold time. Using liquid PCM or panels with a solid/liquid combination decreases the hold time.

Series 4 Prep Method D: Fridge Only Pack-Out Instructions (to prevent freezing)

Panel Prep

2.1 Place panels in a fridge between 5° and 8°C for at least 24 hours before use so the PCM (phase change material inside the panel) is liquid.*

- * Panels may be stored in the fridge until needed for assembly or the PCM solidifies. If a refrigerator maintains 5°C or above, the PCM within the panels will not get solid (the solidifying point is 4.5°C), keeping the PCM liquid indefinitely until pack-out. Liquid PCM panels will protect the product from freezing until the PCM becomes completely solid.

2.2 Shake panels to verify the PCM is liquid. If solid, restart at step 2.1 to ensure the longest hold time. Liquid PCM will prevent the product from freezing (at refrigerator temps) in extreme cold the longest. Using solid PCM or panels with a solid/liquid combination decreases the hold time.

Refrigerator PCM Prep Method D: Fridge Only Pack-Out Instructions (to prevent freezing)

Panel Prep

2.1 Lay panels flat in a freezer until all the PCM (phase change material inside the panel) turns solid. At -15°C/5°F the PCM will solidify in a couple hours.

2.2 Transfer panels into a room temperature environment just before use to allow the PCM inside to rise to the optimal 1°C. Approximate times:

“03” size = 5 minutes

“08” size = 10 minutes

“28” size = 15 minutes

“96” size = 20 minutes

2.3 Wipe off condensate & shake.After frost turns to condensate, the panel is above 0°C. Shake panels to verify that the PCM is completely solid. If liquid is heard, re-freeze (Step 2.1) and proceed. Using liquid PCM decreases the hold time considerably.

After Step 3 (before pack-out), insert a thermometer and close to monitor when the Cool Cube™ gets to the 1°C mark. If below the 1°C mark, wait until it warms up to 1°C before packing out. To speed up the process, transfer panels into a room temperature environment for a couple of minutes and re-check. Pack-out at 1°C will ensure a maximum hold time between 1° and 6°C.

Phase change materials (PCMs) are materials that absorb and release thermal energy during the process of melting and freezing. When a PCM melts, it absorbs the heat from the environment, yet its temperature stays at the melting point until totally liquid. Conversely, when a PCM freezes, it absorbs the cold from the environment, yet stays at its temperature until totally solid. This makes PCM an ideal, passive solution for a variety of applications that require temperature control. The most common PCM is water/ice. Ice is an excellent PCM for maintaining temperatures at 0°C. But water’s freezing point is fixed at 0°C (32°F), which makes it unsuitable for most temperature sensitive applications.

Cool Cube™ PCMs offer custom temperature holds based on their melting point. The PCM inside Series 4 panels has a melting point of 4.5°C/40.1°F. When panels are solid, contents within the Cool Cube™ stay cool (at fridge temps around 4.5°C) in hot conditions during an extended period of time. When panels have liquid inside, contents within the Cool Cube™ won’t freeze (again at fridge temps around 4.5°C) in extreme cold during an extended period of time.

When the panels have reached 4.5°C and are completely solid, they are ready to hold your product. To verify that they are solid simply shake the panel. If you shake the panel and it feels and sounds slushy, with some liquid and some solid it will hold your product at a cool temperature, but it won’t hold it as long as if the panel is completely solid. If you shake the panel and it feels and sounds completely liquid, put the panel back into the freezer/refrigerator and continue to condition until the panel has reached a solid state.

Shake a panel at various times to get to know your panels. For example, shake the panels when you know they are warm to hear and feel how they react when they are liquid.

Within this webpage are several methods for conditioning your PCM panels. The standard conditioning method is performed in the refrigerator. The advantage of the refrigerator is that your panels won’t get too cold. This method can take from 8-24 hours. Alternatively, if you need to use your panels sooner than 8-24 hours, they can be conditioned in a freezer.

PCM panels can be frozen too cold, but there is an easy solution when this occurs. When the panels are frozen to a point below 0°C/32°F, a short staging period is necessary to safely transport your product. If your panels have been stored in the freezer simply take the panels out of the freezer and lay them, individually (unstacked), on a flat surface at room temperature for roughly 30 minutes.

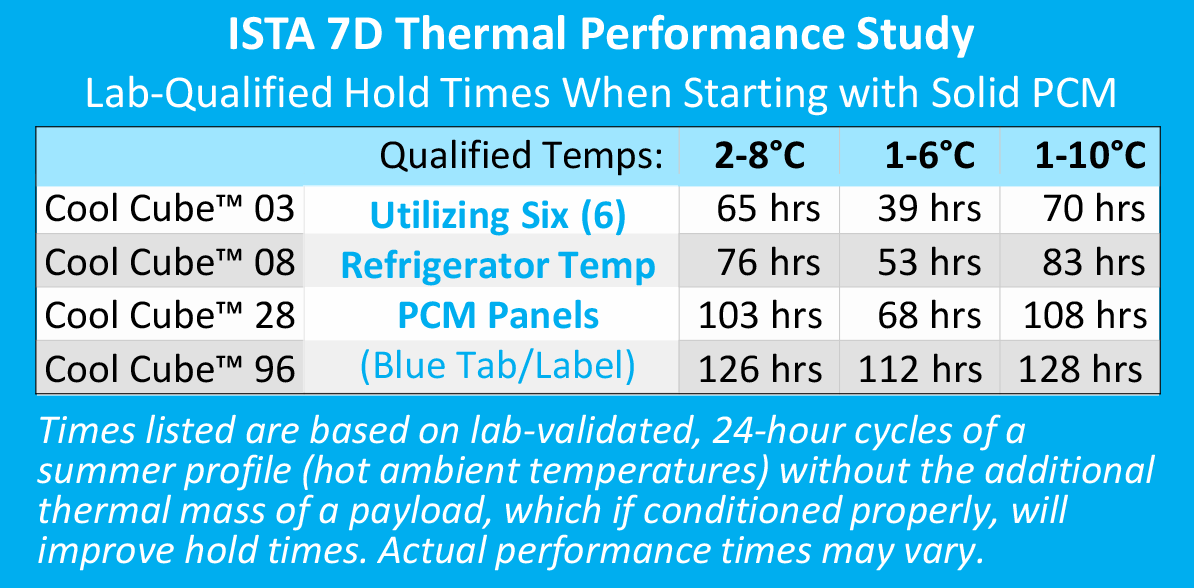

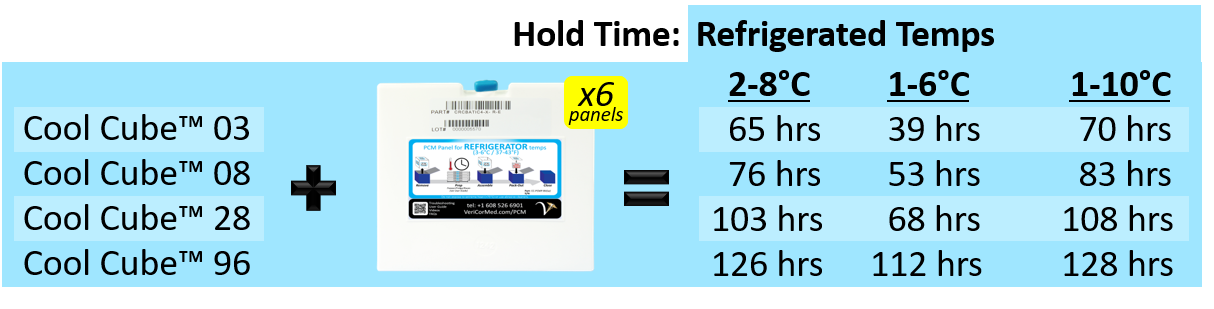

Hold times of the PCM panels vary depending on Cool Cube™ size and desired holding temperature. For example, when properly packed-out into the Cool Cube™ 08, the Series 4 PCM panels can hold the cooler at a temperature below 8°C and above 2°C for 76 hours.

With all pack-out procedures, be sure to use a temperature monitoring device to consistently and accurately monitor the temperature your payload for the entire time it is held in the Cool Cube™. Some regulatory bodies such as the CDC require the use of a certified data logger. VeriCor carries several types of thermometers and digital data loggers that meet the CDC recommended guidelines.

Cool Cube™ User Guide

[wpfilebase tag=file id=433/]

- Always prep the PCM panels before use according to one of the described methods provided by VeriCor.

- Ensure all components are clean and free of damage.

- During prep, enable ample air flow around all panel sides (use spacers or racks).

- Lay panels flat when “freezing”.

- Freeze/melting times vary depending on number of panels being prepped and equipment specifications being used. Assemble using all six panels for maximum hold time.

- Using less panels does not change the holding temperature but does decrease hold time.

- Panels are reusable (10,000+ cycles). (End-of-life disposal: panels use a plastic #2, typically recycled by businesses/communities; PCM is nontoxic and readily biodegradable.)

- Use a calibrated data logger or other temperature monitoring device to observe internal temperature.

- Avoid unnecessary opening of the Cool Cube™ after loading payload. Opening of the Cool Cube™ will decrease hold time.

- An infrared temperature thermometer can assist in ensuring the panels reach a safe pack-out temperature (good for finding out the approximate temperature of each panel).

- Further the temps are away from the melting point, the quicker PCM will change states.

CLICK & PRINT DOWNLOADS (PDF)

You must be logged in to post a comment.