If the Cool Cube™ just doesn’t seem to be working quite right, check out the three most common issues identified below and the possible solutions. If still stumped, give us a call (608-526-6901) or email us (info@vericormed.com) so we can help you out!

The PCM panels are not getting solid.

It usually is as simple as this: the panels are not cold enough for a long enough time.

- Refrigerator Temps PCM melts at 4.5 °C / 40.1 °F. At a minimum, panels need to be <3 °C / 37.4 °F for a day or two to turn solid (at -15 °C / 5 °F the PCM solidifies in a couple of hours). Watch or read about various prep methods here.

- Lab Freezer Temps PCM melts at -21.5 °C / -6.7 °F. At a minimum, panels need to be <-30 °C / -22 °F for a day or two to turn solid (at -40 °C / -40 °F the PCM solidifies in a couple of hours). Watch or read about various prep methods here.

- Room Temps PCM solidifies at 21.5 °C / 70.7 °F. At a minimum, panels need to be <20 °C / 68 °F for a day or two to turn solid (at 5 °C / 41 °F the PCM solidifies in a couple of hours). Watch or read about various prep methods here.

The Cool Cube™ is a passive system that has no moving parts to break. PCM follows the laws of physics. If it (the PCM) gets cold enough, it turns solid; if it gets warm enough, it turns liquid.

Candle Wax Analogy

For argument’s sake, let’s say a candle melts at 90 °F (wax melting points range from 75 °F – 180 °F). In a typical room, the candle remains solid and fluctuates its temperature with the room. However, if the room warms up to 93 °F, the candle slowly melts as it maintains its temperature at 90 °F. Once liquid, the liquid will warm up to 93 °F. Then if the room cools down to 88 °F, the wax will slowly turn solid. To turn wax from a solid to a liquid quickly, put it next to a flame or other heat source. To turn wax from a liquid to a solid quickly, put it in a cool place. Candle wax is a PCM with a melting point of 90 °F (in this circumstance). Cool Cube™ PCM panels have their own melting points. Get the panels below that temperature and the PCM solidifies. Panels warmer than the melting point contain liquid PCM.

It’s not holding the correct temperature for very long.

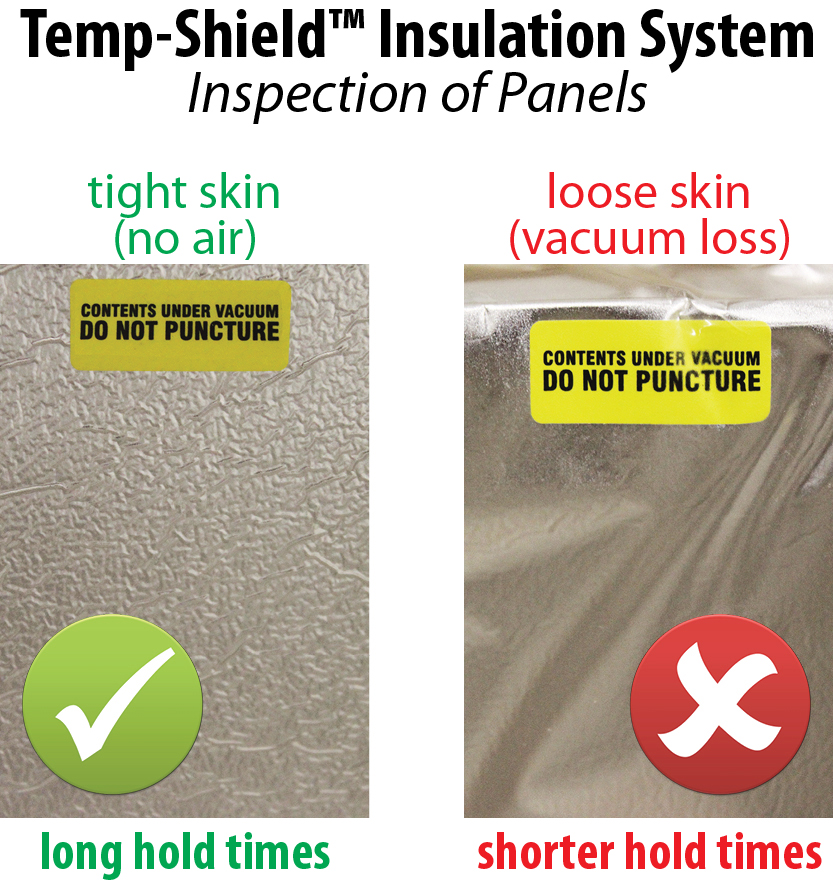

Assuming the PCM panels are prepared properly, the only other part of the system to check is the Temp-Shield™ Insulation System. This system consists of six individually sealed panels that are taped together to form the six-sided assembly. The internal vacuum pressure gives each panel its extraordinary thermal performance. Inspecting each of the panels is paramount, as one compromised panel can affect the entire system. There are two ways to determine whether a panel is compromised:

1) Visually check the skin of the panel (white in older models; silver in newer models) as it should be sucked tight to the core creating a rippled, textured surface. If it is, it still has its vacuum and is good. If the skin has a wave or two and appears loose, the panel has been compromised and will not be as effective.

2) Touching a panel can also tell a lot. Pushing on a good VIP panel, it will seem very rigid and hard. Pushing on a panel that has lost its vacuum will seem soft and squishy.

Inspect and test the entire system periodically, and even more frequently after the first 5 years. Upon testing, if the unit is performing up to requirements, it is fine to use. If it is not holding the temperatures as long as expected, it is likely a VIP panel (or panels) have lost its high R-value due to a vacuum loss. Replace the VIP and you’ll have a whole new system once again.

It’s too cold.

Most likely the PCM panels went into the Cool Cube™ a bit prematurely. To get PCM panels into a solid state, the panels do indeed need to be in an environment colder than the melting point. But realize that the panels are at the stored temperature. When packing out the Cool Cube™, PCM panels AT the melting point should be used. If using “Refrigerator PCM” panels coming out of a freezer (used to get them solid), you MUST let them sit out a while to warm up to 4.5 °C / 40.1 °F. A common reference point is when the PCM panels develop liquid condensate on the outside, they are above 0 °C / 32 °F, so they are getting close. But realize, that if there is any frost on the panels, they are too cold!!!

My problem isn’t on here.

Not to worry. The FAQs page (here) has a multitude of questions as well as a search function. If still stumped, three options remain:

1. Call 608-526-6901 (M-F) to speak with someone.

2. Email (info@vericormed.com) details about your issue anytime.

3. Ask a question here ↓

We are working on building the rest of this page out, so please check back soon. However, if you are really anxious and waiting for what is to come, send us an email at info@VeriCorMed.com to give us a nudge.