Think of the Cool Cube™ as a super-smart cooler designed to keep important things like vaccines and medicines at the perfect temperature during transport, off-site use, or contingency backup scenarios. It has three main parts that work together to do this job really well.

Three Key Players

- Patented PCM (Phase Change Material) Panels: Imagine reusable ice packs, but way more sophisticated. These panels are filled with a special material that soaks up or releases heat to keep the inside of the Cool Cube™ just right. They come in different temperatures (to match the needed temperature range of the payload) and sizes (the fit the various sizes of the Cool Cube™).

- Temp-Shield™ Insulation System: This is super-advanced insulation on all six sides of the Cool Cube™. It’s made of special material that is incredibly good at blocking heat from getting in and cold from getting out, keeping the temperature stable for a long time.

- Protective Transport Case: This outer shell holds everything together, protects the Temp-Shield™ Insulation System and makes it easy to carry the Cool Cube™ safely.

Let’s take a closer look at each of these parts, explaining their functionality, importance, and contribution to the overall effectiveness of the Cool Cube™.

PCM Panels

How They Work

Think about ice melting. When ice melts, it absorbs a lot of heat without getting much warmer itself. These PCM panels work on a similar idea, but with materials that can switch between solid and liquid at specific temperatures. This “phase change” allows them to absorb or release a lot of heat, keeping the temperature inside steady. You might have heard this called “latent heat” – it’s just the science behind how these materials store and release energy.

Comparing Traditional Ice and PCM

| Ice | PCM | |

| Precision | Risk of Freezing Damage: Direct contact with ice packs can expose temperature-sensitive products like vaccines and biological samples to damagingly low temperatures, potentially reducing efficacy. | Safe Alternative: PCM panels maintain specific temperature thresholds, eliminating the risk of accidental freezing. For example, refrigeration PCMs (2-8°C) ensure vaccines remain within their required range, preventing overheating and freezing. |

| Buffering Needs | Buffering Material is Needed: Ice and gel packs often require additional buffering materials to prevent direct contact with the product and mitigate the risk of freezing. This adds bulk and reduces the usable space within the transport container. | No Need for Buffering Material: PCM panels regulate temperature at the precise required range, negating the need for extra insulation layers. This improves space efficiency within the Cool Cube™, allowing for a greater payload capacity without increasing the external dimensions. |

Lab Freezer Temps PCM (Grey)

- Temperature Range: -50° to -15°C

- Application: Designed for frozen vaccines (e.g., varicella, MMRV, zoster) and fresh frozen plasma.

- Phase Change Point: -21.5°C (-6.7°F)

- Key Benefits:

- Provides ultra-low temperature storage, serving as a reliable alternative to dry ice.

- Mitigates the risk of the product warming excessively.

- Engineered for frozen biological materials requiring dependable thermal stability at a low temperature.

Controlled Room Temps PCM (Tan)

- Temperature Range: 15°-25°C, 20°-24°C

- Application: Suitable for FFPE tissue, platelets, and various biospecimens needing to be kept at room temperature.

- Phase Change Point: 21.5°C (70.7°F)

- Key Benefits:

- Maintains stable warm temperatures for extended periods, preventing exposure to extreme cold or heat.

- Optimal for biological specimens requiring consistent ambient conditions.

- Eliminates the need for bulky additional buffering materials.

Refrigerator Temps PCM (Blue)

- Temperature Range: 2-8°C | 1-10°C | 1-6°C

- Application: Ideal for vaccines, medicines, blood products, tissues, and organs.

- Phase Change Point: 4.5°C (40.1°F)

- Key Benefits:

- Ensures stable refrigeration temperatures without the risk of freezing.

- Offers a safer and more effective solution compared to ice packs.

- Utilized in the VT Line for vaccine and medicine transport and the BT Line for blood products, tissues, and organ transport.

Types of PCM Panels

Cool Cube™ PCM panels are specifically designed to meet various temperature requirements and are color-coded for easy identification.

Why They’re Great for the Cool Cube™

- Temperature smart: They’re designed to keep things at a very specific temperature, preventing dangerous spikes or drops.

- Perfect fit: Each Cool Cube™ has six of these panels that fit together (easily) inside the insulation. This makes sure the temperature is even throughout the whole cooler.

- Better than ice: They can store way more “coolness” than the same amount of ice, they maintain a much more consistent temperature, and temperature they are at is specialized for the application—fridge, frozen, or room temperatures (ice is at 0°C/32°F…that’s it). Plus, no messy melting water!

- Reliable: They can go through many cycles of freezing and thawing without losing their ability to control temperature.

- Create a full barrier: The edges of these panels are specially shaped so that when they’re all in place, they form a continuous one-inch-thick layer of the temperature-controlling material all around what you’re transporting. This gives you the best temperature protection from all sides.

- Work in tough conditions: They help keep your supplies safe even if the outside temperature is really hot or cold.

Temp-Shield™ Insulation System

What It’s Made Of

The Temp-Shield™ is made of six special panels called VIPs (Vacuum Insulated Panels). Think of them like high-tech insulated walls. Inside, they have a material called fumed silica, which is amazing at stopping heat. Each panel has several layers.

- The super insulator (fumed silica): This is the main part that blocks the heat.

- A protective layer (non-woven fabric): This keeps the silica safe.

- A vacuum seal (metallic barrier film): This is crucial! By removing the air, which carries heat, it makes the insulation incredibly effective.

- A tough outer layer (transparent polycarbonate): This protects the vacuum seal from getting damaged.

Why It’s So Good

- Super heat blocker: These VIP panels are way better at stopping heat than regular insulation, meaning the inside of the Cool Cube™ stays at the right temperature for much longer.

- Saves space and weight: Unlike bulky foam insulation, these panels are thin but powerful, giving you more room inside the cooler for your supplies without making it too heavy to carry.

- Long-lasting performance: The vacuum seal keeps the insulation working effectively for a very long time – up to 20 years!

- Works in a wide range of temperatures: Whether you need to keep something very cold or just cool, this insulation can handle it.

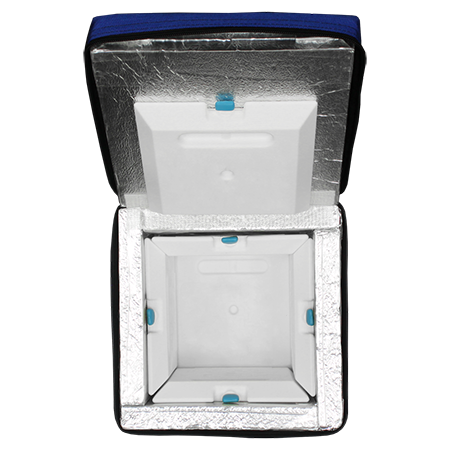

How It Works with the PCM Panels

The Temp-Shield™ and the PCM panels are a team! The VIP panels surround the PCM panels, creating a completely insulated box.

- Keeps outside temperatures out: The insulation stops the outside heat or cold from affecting the temperature inside.

- Helps the PCM work better: The PCM panels do the active work of absorbing or releasing heat, and the insulation helps them do their job efficiently by minimizing how much they have to work against the outside temperature.

- Strong and stable: The way the VIP and PCM panels fit together makes the whole system strong and prevents things from shifting around inside, which helps keep the temperature even.

- Longer cooling time: By having such good insulation, the PCM panels can keep things cool for a longer period without needing to be recharged.

Protective Transport Case

What It Does

The outer case of the Cool Cube™ is designed to be tough and practical for transporting your important supplies. Different sizes have different features to make them easy to move.

Why It’s Important

- Keeps everything safe: The strong outer shell protects the inner insulation and PCM panels from bumps, drops, and the environment.

- Easy to carry: It has handles, straps, and sometimes wheels, depending on the size, so you can move it around easily and comfortably.

- User-friendly: Features like outside pockets, double zippers, and access points for temperature probes make it easy to use and monitor.

- Meets regulations: The sturdy design helps ensure that you meet the safety rules for transporting sensitive medical and lab items.

The Cool Cube™ Family

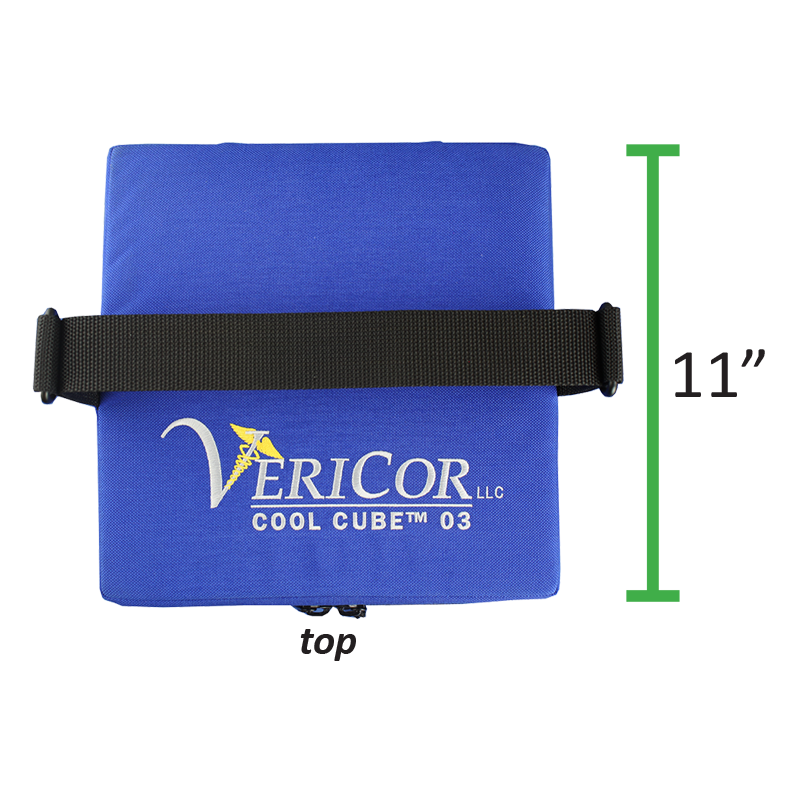

Cool Cube™ 03

- Usable Space: 5 ¾” x 5 ¾” x 5 ¾”

- Outer Dimensions: 11” x 11” x 11”

- Portability Features: Compact and lightweight, equipped with a carrying handle, shoulder strap, and clear external pockets for accessories.

- Best For: Transporting smaller quantities of temperature-sensitive materials.

Models of the Cool Cube™ 03

Cool Cube™ 08

- Usable Space: 11 ¼” x 6 ½” x 6 ½”

- Outer Dimensions: 16” W x 11 ½” D x 11 ½” H

- Portability Features: Larger than the Cool Cube™ 03 but still easily carried, featuring a shoulder strap, multiple pockets, and a dual-zipper design for enhanced convenience.

- Best For: Transporting vaccines, specimens, or lab materials.

Models of the Cool Cube™ 08

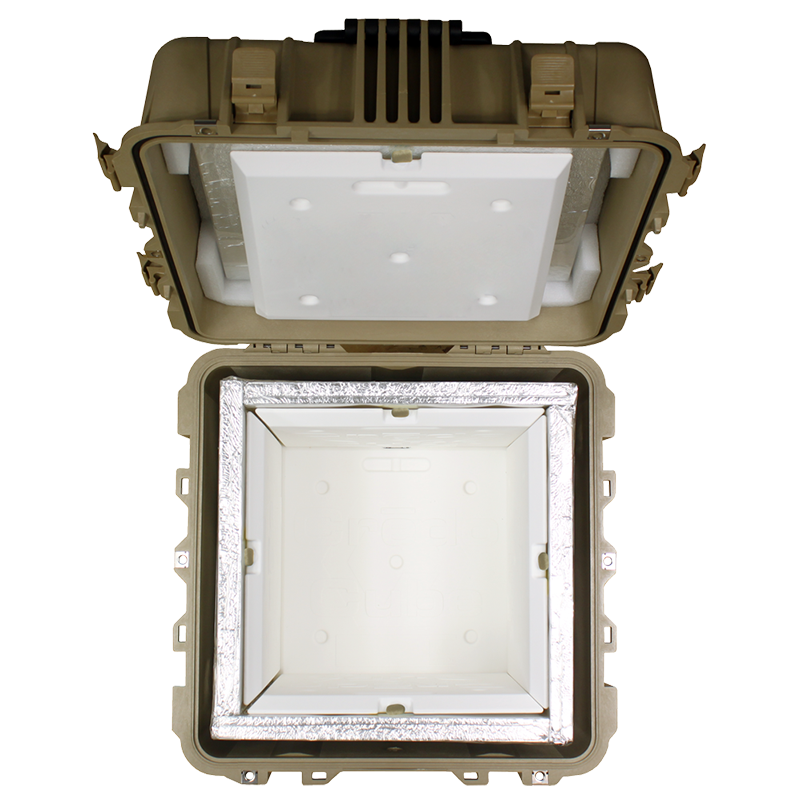

Cool Cube™ 28

- Usable Space: 12” x 12” x 12”

- Outer Dimensions: 20 ½” W x 20 ½” D x 23” H

- Mobility Features: Incorporates a Tru-Trac System™ and a fold-out tow handle, enabling efficient movement of payloads exceeding fifty pounds.

- Best For: Preparedness plans, large-scale medical transport, and extended storage needs.

Models of the Cool Cube™ 28

Cool Cube™ 96

- Usable Space: 18” x 18” x 18”

- Outer Dimensions: 26 ½” W x 26 ½” D x 28 ¼” H

- Mobility Features: Equipped with four swivel wheels, allowing for the efficient movement of payloads exceeding eighty pounds.

- Best For: Bulk storage and transport of high-value temperature-sensitive materials.

Models of the Cool Cube™ 96