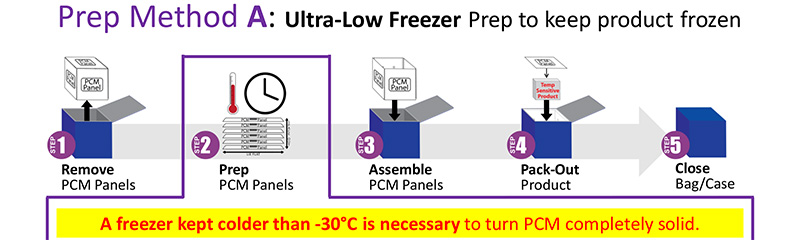

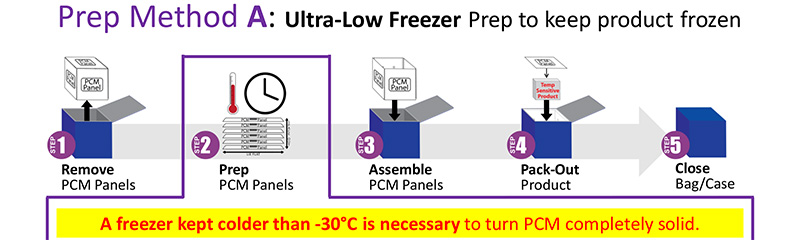

Prep Method A: Ultra-Low Freezer Prep to keep product frozen

Panel Prep

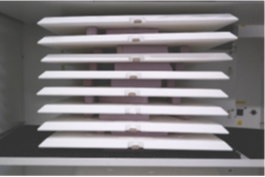

2.1 Lay panels flat in an ultra-low freezer until all the PCM (phase change material inside the panel) turns solid. At -25°C/-13°F the PCM will solidify in a day or two.*

* If the freezer temperature is ever warmer than -25°C, PCM may not get completely solid (due to the possibility of supercooling). If panels are stored within the temperature parameters of the product but the PCM is liquid, panels may be used but the hold time will decrease.

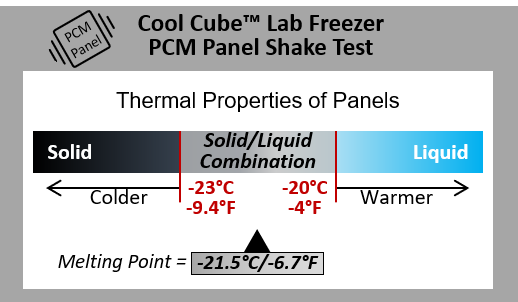

2.2 Shake panels to verify the PCM is solid. If there is liquid, restart at step 2.1 to ensure the longest hold time. Using liquid PCM or panels with a solid/liquid combination decreases the hold time.

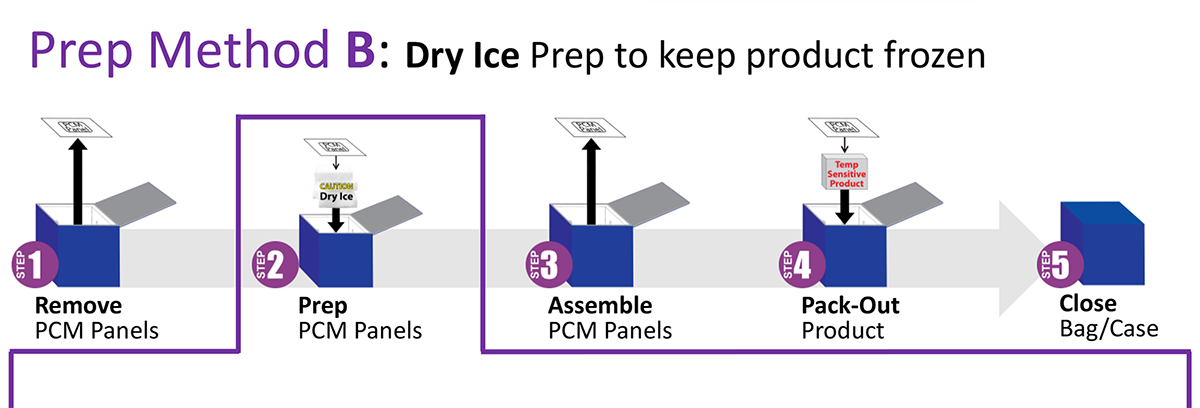

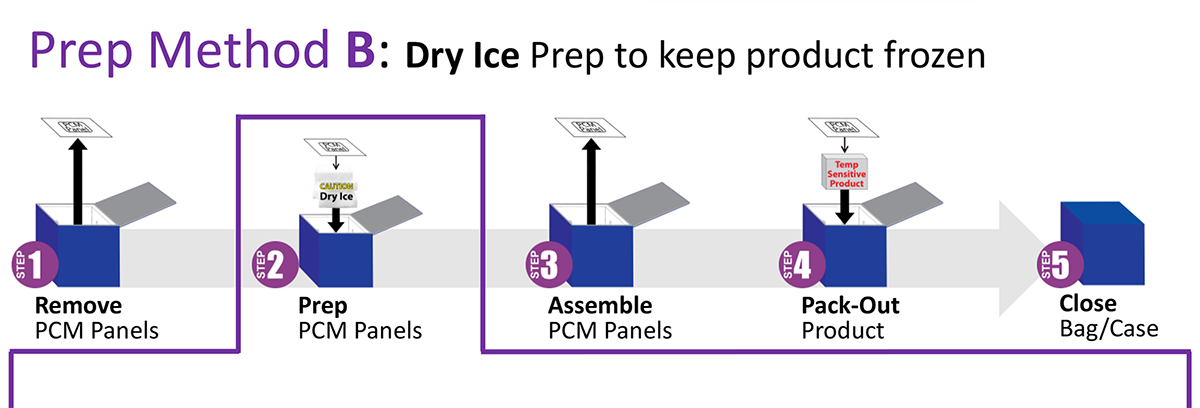

Prep Method B: Dry Ice Prep to keep product frozen

Panel Prep

2.1 Pack out cooler with dry ice until the PCM (phase change material inside the panel) panels become solid. The more dry ice, the faster the PCM will solidify.*

* Time varies dependent on the starting temperature of the panels, size of panels, and amount of dry ice used. CAUTION: Dry ice has a surface temperature of -78.5°C/-109.3°F, so handle with care.

2.2 (Optional) If product to be packed out cannot withstand an initial -70°C temperature, transfer panels into a standard freezer at least 3 hours before use. Panels may be stored in the freezer until needed for assembly or the PCM melts.

If a freezer maintains -23°C or below, the PCM within the panels will not melt (melting point is -21.5°C), keeping the PCM solid indefinitely until pack-out. If the freezer maintains -21.5°C or above, periodically check for melting and restart at step 2.1 to ensure the longest hold time.

2.3 Shake panels to verify the PCM is solid. If there is liquid, restart at step 2.1 to ensure the longest hold time. Using liquid PCM or panels with a solid/liquid combination decreases the hold time.

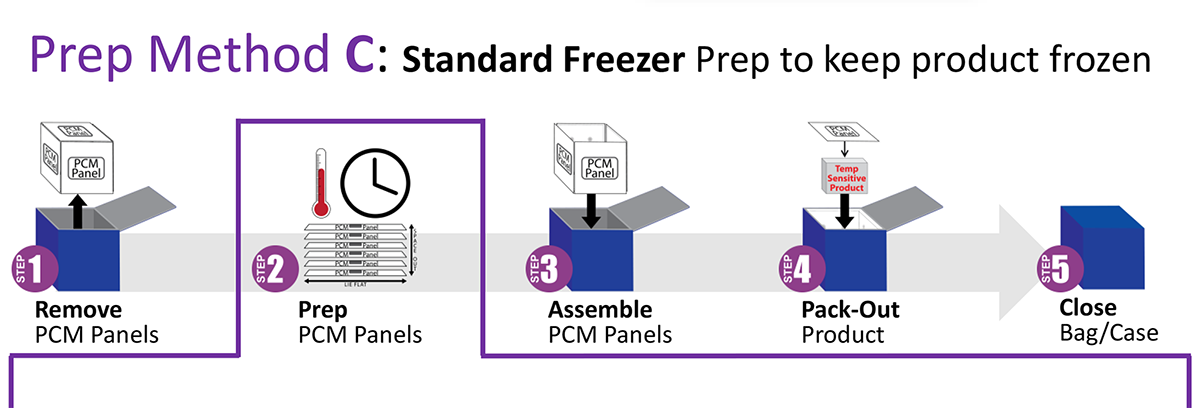

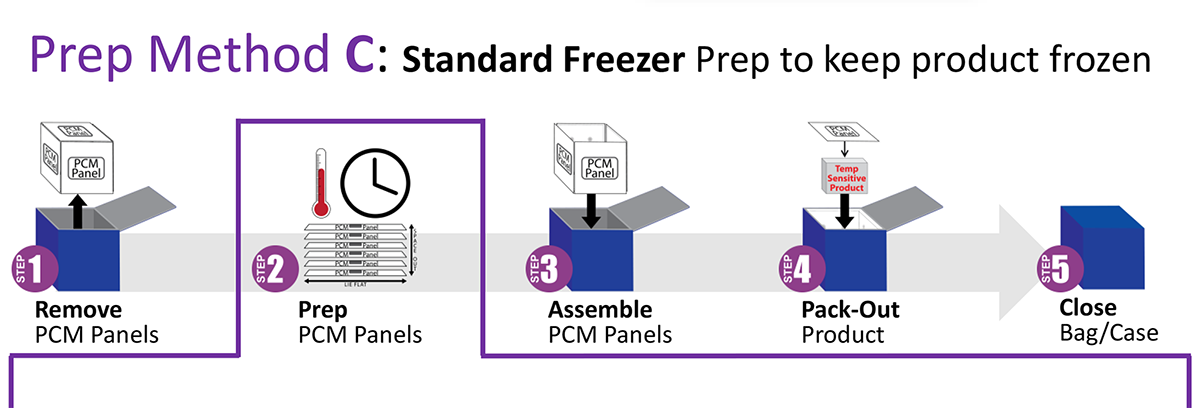

Prep Method C: Standard Freezer Prep to keep product frozen

Panel Prep

Store panels in a standard freezer (turned down to its lowest setting) for a minimum of 24 hours before use. Unless the freezer is always below -23°C, the PCM (phase change material inside the panel) will never turn completely solid, but short-term use is still possible.*

* Although PCM is liquid, it is at the temperature of storage environment after 3 hours. For instance, panels stored in a -18°C freezer are at -18°C even PCM is liquid. Assembling the Cool Cube™ with this additional thermal mass will keep product frozen, just for a shorter amount of time than the lab-validated results.

Shake panels to check the state of the PCM (phase change material inside the panel).

- If liquid…panel is at the freezer temp but above -20°C; anticipate shorter hold times.

- If solid…panel is at the freezer temp but below -23°C; ideal for maximum hold times.

- If solid/liquid combination…panel is at the freezer temp between -23 and -20°C; monitor longer use periods.